Why Is Vibration Analysis Needed? - HECO

October 30, 2019

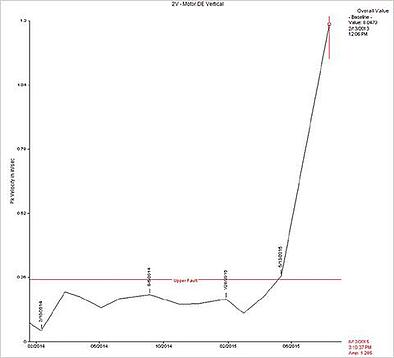

Industrial vibration analysis is a measurement tool used to identify, predict, and prevent failures in rotating machinery. When analyzing machine frequency vibrations, (frequency analysis) it is normal to find a number of important frequencies that are directly related to the movement of various parts of the machine. Vibration may influence the durability and reliability of machinery systems or structures and cause problems such as damage, abnormal stopping, and catastrophic failures. Vibration measurement is an important countermeasure to prevent these problems from occurring.

There are three main parameters that are measured to evaluate the vibration characteristics of any dynamic piece of equipment as displacement, velocity, and acceleration. The analysis of vibration monitors the characteristic changes in rotating machinery caused by imbalance, misalignment, bent shaft, mechanical looseness, faults in gear drives, defects in roller bearings or sleeve bearings.

The over all goal of vibration analysis is to identify faults with a rotating piece of equipment and then alert personal that some type of action needs to occur when the needed frequency of the data collection is not aligned with the maintenance strategy. Vibration analysis can help detect these failures before they occur, helping to reduce downtime and increase reliability in your plant.

HECO Motors Performance Systems has the capabilities to provide this type of field service to their customers. Our Predictive Service Group (PSG) has a proven track record in the industry to keep our customers critical rotating machinery up and running by providing on-site maintenance and reliability services.

<INSERT LINK TO: Download Reliability Maintenance is Good Medicine>

HECO – All Systems Go

269-381-7200

About the author:

Steve Mazziotta is a 20+ year veteran of the electric motor industry and is an Account Manager for HECO – All Systems Go in Northern Indiana and Northern Ohio. Steve has been involved with multiple large armature and field frame transportation and repairs over state lines and does work on AC-DC drives. He has also done on-site field services for large DC equipment in steel mills, AC projects and contracts on government entities.

Posted in Predictive