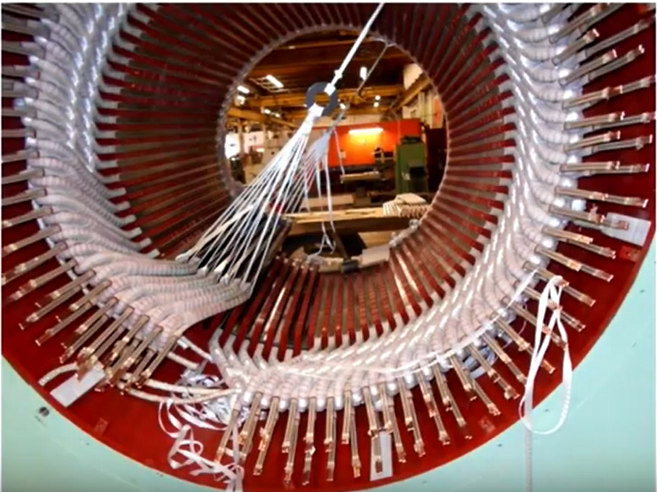

Case Study 5500HP, 13,200v, Synchronous Motor: (Part 6) Stator Redesign and Rewind - HECO

July 25, 2019

Below is a 2 minute clip of an hour long presentation given by Todd Hatfield during the 2018 RPM Symposium. Part 6 of this 8 part series focuses on the redesign and rewind of the stator for the 5500HP, 13,200v, synchronous motor.

This video will describe:

- The new engineered stator winding design and CAD drawing

- Using a DC welder to heat the coils, allowing them to be more flexible in order to keep them from cracking

- Connecting the leads to match the original 5500HP, 13,200v, synchronous motor

Make sure to read the rest of the series starting with…

- What is an AC Synchronous Motor?

- Part 1 – Problem Identification and Potential Solution

- Part 2 – Evaluating Surplus Motor Option and Initial On-Site Application

- Part 3 – Electrical and Mechanical Redesign Engineering

- Part 4 – Mechanical Design of Shaft and Rotor

- Part 5 – Electrical Design of Rotor

Posted in Field Service, Predictive, Repair