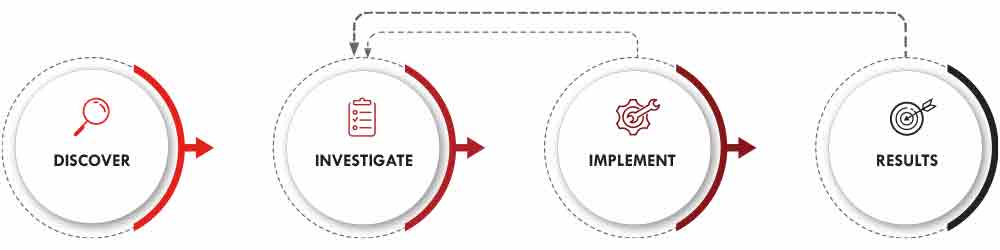

The HECO Process

Our simple approach to complex issues

HECO helps Midwest manufacturers, utility companies, and converters within a wide variety of markets that value “quality and reliability” over “price and temporary solutions.”

Our customers trust us to ask the right questions and do what’s right for them. They appreciate our honesty, embrace our innovative approach, and share our thought process as a partner, not just a supplier.

Through a mix of Repair, Product Sales, Field Service, Predictive, and Equipment Management, we help customers do three things better:

1. See what’s going on.

2. Get rid of the issue.

3. Stop the issue from happening again.

Doing that provides our customers peace of mind and confidence that their motors and equipment will operate effectively and have longevity and reduced total cost of ownership.

The HECO Process resolves complex issues without frustrating and costly rounds of trial and error. By educating ourselves and all stakeholders, we simply deliver results.

Discover

Initial Meeting

- Get to know your business

- Get to know our business

Identify Issues

- Ask the right “why” questions

Technical Validation

- Joint call/visit

- Shop tour

Onboarding

- Our customer system

- Your vendor system

Investigate

Repair

- Pick up

- Disassembly and inspection

- Observations and findings

- Job estimate and report

Predictive

- Tailor program based on criticality

- Route and/or APOLLO quote

- Troubleshooting (data collection and analysis)

Product Sales

- Technical review

- Find options and; provide quote

Equipment Management

- Walk-through and initial assessment

- Design system and quote

Field Service

- Troubleshooting

- Site visit

- Quote

Implement

Repair

- PO approval

- Job repaired and documented

- Final test run + QA/green tag

- Delivery/shipping and report

Predictive

- PO approval

- Route data collection and analysis

- Monitor and analyze with APOLLO

- Perform corrective actions

- Report with recommendations

Product Sales

- PO approval

- Print approval (if required)

- Supply product

Equipment Management

- Tag and survey

- Program implementation

- Manage via TracRat®

Field Service

- PO approval

- Perform work

- Report

Results

See What’s Going On

- Proactive monitoring creates a view of equipment condition and vulnerability

Get Rid of Issues

- Utilizing data, services, and solutions, you can be proactive before a failure occurs

- If a failure occurs, HECO has the tools and resources to identify the issue, respond, and correct it the right way

Prevent Future Issues

- Long-term reliability and reduced total cost of ownership creates peace of mind